Why does your argument sound like its coming from an industrial competitor?

Why does your argument sound like its coming from an industrial competitor?

I am the Stig

there have been so many concepts, quasiturbine, carnot cycle engines even the wankel this is just another trial and a poor one i might add

with this engine, the size or the surface area or volume to area ratio is inadequate, that means the engine will be heating the atmosphere not expanding

and what is this about increasing rpm to produce more power, sure it is done in f1 but it is extremely difficult to produce the same result in real life despite engine size, cbr motor at 600cc goes to 16,000 rpm, thats the best i have seen. this engine is better of being used as an oil pump or a personal vibrator rather than the current use

Last edited by kigango123; 09-15-2006 at 02:09 PM.

Once fanboyism infects you it impares all your judgement.

It's like being drunk, you lack common sense and everyone laughs at you.

Revetec has ben under development for about ten years. At the moment we have not been interested in performance engines so let's refer our engine design to performance in regards to fuel economy. We have produced a very flat torque curve which provides great acceleration right through the range. Our engines have been tested by automotive companies overses and we have replicated this . Another thing is that the fuel consumption remains constant under full load right through the rev range which is not seen in any other engine in the world.

I'll get one thing straight right now. We do not release most of the information about our engine as we protect our technology. We have not disclosed our actual design and guiding system for the pistons. We have almost perfected the design and are currently building our next model which all engines in the future will be based on. We have drastically reduced the size of our engine and reduced the amount of components. We have had no problem with gearing. Because of our new piston guiding system, we have no problem with piston twist.

Our engines in the past have been strictly development engines. Every time we change the Trlobe cam design the balancing changes. This is why up to date we have not balanced any of our engines as it has not been required for the type of development work we have been carrying out. Our new engine is fully balanced. Our reciprocating mass is smaller than other engines of the same capacity, and our stroke is shorter reducing the mass required for balancing. We used the subaru heads on our last engine purely because they roughly suited our last engine layout and our next engine will use heads developed in-house.

I think that most people don't understand our engine due to the fact we have not released certain information. I'll tell everyone now that the cylinder heads are operating at the same speed as a conventional engine. ie. The pistons stroke 2 times (1Xup and 1Xdown) per output shaft revolution (the same as a conventional engine), so there is no overspeeding of the engine's top end. Please remember we have not released all engine features and operation information. You will all have to be a bit patient.

I'll also state now that the formulas that work out power and torque do not work on our engine so all of you engineers that are trying to work out figures for our engine, your standard engine calculations will not work. We have proved this to several large automotive manufacturers and the like plus the figures we get in actual testing verify this.

A development program is just that. Trialling different engine layouts to evaluate different design features. Trialling a new design always creates unforseen problems and failures which then steer the design into the correct layout. Failures are normal for a development program, as with every new design longer endurance testing takes place. We are now in a postion that our next engine is ready for the testing required by engine manufacturers to evaluate in performance, fuel economy and initial endurance testing. Every automotive manufacturer in each region has different operating enviroments. So each engine has to be tested and modified to reach those standards in each region. Say for instance that an engine in Australia is different from one in another country even though the car model is the same. This is why the final endurance testing is not done by us rather an by the automotive company evaluating the engine technology for production.

What I can say is that we are nearing the end of development that is required before production of our engine is performed.

Stay tuned to our website www.revetec.com over the coming months as soon we are going to release info about our new engine. We are very excited about it and it will suprise everone in the engine field. We have now lodged a new patent world wide on the new design.

I will check this forum time to time so if you have any questions please post them as I will try to answer them when I have time.

Cheers

Brad Howell-Smith

The comment about misleading marketing is incorrect. All marketing the company has released is acurate. We are not bound to release all information about our engine and for security of our technology we reserve the right to hold back information. I have just returned from overseas where I presented to a board of about 8 senior engineers from a leading automotive supplier and the statement from them was "this is a step up technology".

We have proven in actual testing our flat torque curve and a flat fuel usage over a varying rev range. This has been done by a leading automtive company in their facility, fully independantly. I know many of you out there have a lot of questions because you don't have the full picture about what we are doing and I hope to disclose the rest of the information soon. I can say that we have presented to many of the world's top engine manufacturers including 2 Japanese car manufacturers and we have been able to satisfy all their questions posed to us. This technology is hard for them to comprehend so I don't expect you all here to understand what we are doing from the limited information.

As regards to the 1.3L Suzuki Hayabusa engine. Outright performance is not what this is all about. This engine is all about saving fuel by providing consistant torque throughout the rev range reducing the need to rev an engine into the higher power and rev range. By doing this fuel consumption is reduced dramatically. No doubt performance models will evolve to exceed conventional engines in the performance area. I know most of you are interested in the perforance area but I'll tell you now that that is not where most of the market sits. The current engines are directed at markets where fuel usage and pollution problems exist.

Regards

Brad Howell-Smith

Dear Pneumatic,

Firstly that you are quoting old reports that the engine does 6 strokes per rev. The graph you are showing is of a revetec engine that has 2 strokes per rev. You may note that in the pictures that the valve train is running a 3:2 ratio on the belts but what is not shown is the 1:3 to the output shaft as the output shaft on that engine does not protude out of the engine case at the front. Maybe I should get our website design company to update some information that we can disclose to make things clearer.

Secondly, the engine you are comparing is a high performance engine, not an engine setup for a production car with only fuel economy and emissions in mind. Performance models will evolve but even the valve grind we are using is similar to existing automtive engines that are manufactured with economy in mind. Let's compare the Toyota Prius engine with the 1.3L Suzuki Hayabusa engine. Or the sukuki engine with a F1 engine. They are as different as the comparison you are making so it is meaningless. We have compared our engine to the prius engine (Minus hybrid) and the vectra engine that is currently in production. Two engines that provide good fuel economy.

Does your suzuki engine feel as powerful at 1,500rpm as 6,000rpm? Your engine feels most powerful (best acceleration) where the torque peak occurs. At 6,000rpm you are using 3-4 times the fuel to accelerate the same. Have you ever seen a BMEP pressure map and then compared it to a mechanical efficincy graph. It is funny to think you believe that the peak pressure is only at the same point of a crankshaft's maximum efficincy point and there is no pressure on the piston at any other point. Fuel mixtures, load and rev range vary the peak pressure's postion. Ignition timing get's the pressure point as close to this position but has limitations to the amount that can be used due to detonation and the like. If you were to graph the above mentioned at the maximum point you will realise that the losses are around 36%. It is far worse at lower rpm's and at a partial throttle, where most driving occurs. Please find the thermal efficiency figures of the suzuki engine at a varying load and rev range, especially at the point where most operation occurs. The proplem occurs in evaluating an engine when the peak power is considered.

A friend of mine had a truck which had high torque at low revs which he replaced with another with higher power. He found that the new truck had to be revved higher to produce the power. Fuel economy was worse under the same operation conditions and he felt he had to abuse the engine to gain the same performance with the same load. This is why a large torque band in a lower rev range is so important.

I'm not having a go at you. I'm just trying to explain why we are doing what we are doing. There are many things that we have experienced in our testing we are still trying to fully quantify, such as when we program an engine fuel injection on the dyno that the fuel injector duty cycle reduces when the revs and load are increased. This has never been seen in an engine before and it will take many years of analysis to fully understand what we have experienced in hard tests. All I can say is that we have had to take engines OS to prove the torque and fuel delivery maps under independant testing by because it seems impossible to engine manufacturers that we are talking to. They have to see it with their own eyes on their own equipment. This has been done.

Regards

Brad Howell-Smith

Dear Pneumatic,

So let us refer to your graph before you put the gearing factor in which is incorrect due to the fact that those figures were produced on an engine with 2 strokes per rev being the same as the compared engine. We are producing more power in the normal automotive rev range and producing almost the same peak torque at 3,500rpm compared with 6,500rpm of the 1.3L Suzuki Hayabusa engine, when the fuel usage would probably be double. Note again that the lower the revs that the torque is applied the better. This is an automotive vehicle engine prototype. Knowing this I think you would be silly to say that our engine doesn't save fuel dramatically in an automotive application. Maybe in the future we we develop an engine that has the same application as the Suzuki Hayabusa engine. The figures would be very interesting due to providing engine breathing at the same RPM and extending the flat torque curve to a higher RPM range. We actually produced a better and dead flat torque curve very recently at a leading engine manufacturers facility. Our next engine will even be better.

Last edited by revetec; 10-03-2006 at 09:03 PM.

I came across this thread today.

Please take a look at http://www.pattakon.com/greco/index.html or start from http://www.pattakon.com

and select either the ‘GRECO animations’ or the ‘GRECO theory’ topics. There are some 20 animations.

Then forget all about crankless engines, return to the present conventional TESTED technology and take a good look at http://www.pattakon.com/pre/index.html (or get into pattakon's site and select the Pulling Rod Engine – NOT the Pulling Piston Engine which is its father – ).

If you have to select just one animation of the Pulling Rod Engine, try the http://www.pattakon.com/pre/PRE13.exe or

http://www.pattakon.com/pre/PRE14.exe or http://www.pattakon.com/pre/blueprint.pdf .

Thank you

Manolis Pattakos

Dear Manolis,

Re: Pull rod engine

Unless you are doing formula1 RPM's (18,000RPM) a conrod ratio of around 1.65:1 is desireable to achieve the correct piston acceleration. The higher the RPM's the higher the conrod ratio required. A normal car is around 1.6:1 - 1.7:1. Is this Pull rod configuration engine a automotive production engine or a 18,000RPM one? If it is aimed at the car market then:

This company doesn't know anything about breathing. Any engine of this kind has a slower initial piston speed which decreases the initial gas flow past the valve. We have investigated using a cam with a perfect sine wave in piston acceleration and we have found that any engine with a con-rod to stroke ratio of anything over 1.7:1 reduces breathing and requires supercharging at lower RPMs or non standard valve timing when getting over 2:1. The problem with many people is that they don't understand engines properly and even though some theory may look good and the design looks simple, doesn't mean there are no inherant problems with what they are trying to do.

BTW. Let's see an actual engine run with figures of this pull rod engine.

Brad

PS. I modified my response so as not to be so agressive as I think I went overboard and was probably having a bad day reading all the threads. Sorry If I upset anyone! :-)

Last edited by revetec; 10-19-2006 at 07:26 PM. Reason: Not clear enough.

Dear Brand,

Thank you for your reply.

You wrote : This company doesn't know anything about breathing. Any engine of this kind has a slower initial piston speed which decreases the initial gas flow past the valve. We have investigated using a cam with a perfect sine wave in piston acceleration and we have found that any engine with a con-rod to stroke ratio of anything over 1.7:1 cannot breathe properly and requires supercharging.

It seems you never heard that all Formula1 and GP-moto engines use con-rod to stroke ratio well above 1.7:1 (most above 2.0:1). And they do not use supercharging. It seems they know nothing about breathing (AND combustion).

You wrote : The problem with amatures like these people is that they don't understand engines and even though some theory may look good and the design looks simple, doesn't mean there are no inherant problems with what they are trying to do. Companies like this just burn investors money without having any prospect of getting an engine to perform or get to production.

I declare publicly today, to any one of pattakon’s investors to brink me their shares and I will buy them - immediately - a million times their initial price in US dollars (i.e. for each dollar the investor – any investor – gave, he will take a million dollars in return).

Pattakon makes the only continuous VVA (variable valve actuation) engine in the world capable of revving over 9000 rpm. BMW do not use their valvetronic VVA system in their sport cars because they cannot.

We can arrange a test drive for you (or any other professional). Take a look at the http://www.pattakon.com/vva/VVA_Idle/VVA_Idle.htm and the video http://www.pattakon.com/vvar/OnBoard/A1.MOV etc, etc in www.pattakon.com site.

Once again: I call any professional willing to have a test drive with pattakon’s cars to call me.

And a special offer – it is the challenge you asked for -for you: come for a test drive in Athens and if you see less than I claim, I will pay your first class airplane tickets.

Just to find out who is giving the engine development industry a bad name and who is burning investors money.

You wrote : Let's see an actual engine run with figures of this pull rod engine. You'll never find one now or in the future because in real life it wont work properly.

I admit, there is no yet a Pulling Rod Engine prototype.

But take a look at the pattakon’s US patent 6,062,187 and then HONDA’s US patents 6,763,796 and US 6,786,189 ( http://www.uspto.gov/patft/index.html ). It seems HONDA’s staff do not know that con-rod to stroke ratios above 1.7 cannot breathe properly. Please inform HONDA, too, to stop wasting their time over such crap.

Thanks

Manolis Pattakos

what the.........

people like u dont need to be on this go to supid land where your mind is ass - toyota4ever

ricers suck...pasta rockets for life - sicilian973-2

Dear Manolis,

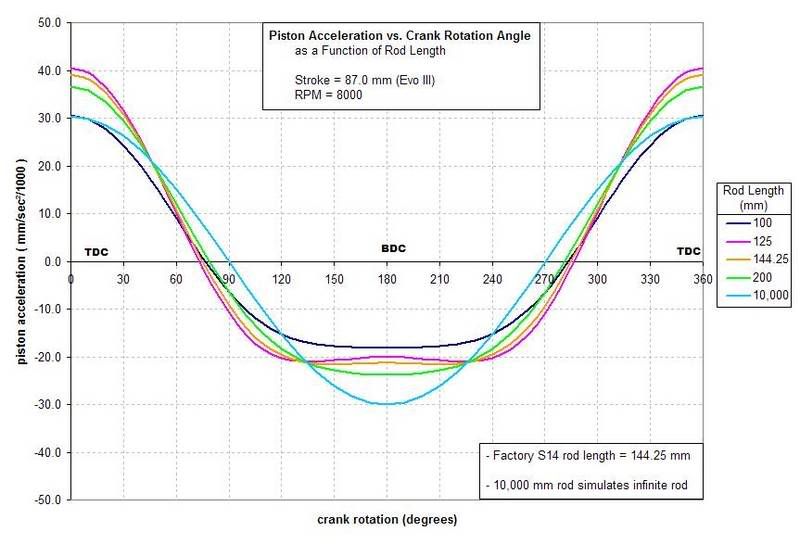

Ferrari F1 engines use slightly greater than a 2:1 conrod ratio but this is to reduce side thrust and allows a lighter piston to be used but most importantly to lower the piston speed down to 24.8 m/s when doing 18,000rpm. Some other formula 1 engines are using down to 1.7:1 conrod stroke ratio and a stroke down to almost 41mm when looking for better performance around the 12,000-15,000 rev range giving similar piston speeds at the desired rpm range. An Evo uses a 1.66:1 conrod ratio which puts the piston speed at maximum acceleration around 20 m/s at 8,000rpm which is a good basis for talking on an on-road application.

If you look at the piston speed chart below you will see that the sweetspot for good initial piston speed creating good velocity past the valves happens between 1.5:1 and 1.7:1 (130mm and 148mm) at which provide low piston speed at BDC for volumetric efficiency and mid piston speed 18-20 m/s. Above 2:1 initial velocity is decreased and BDC dwell is decreased. The endless conrod theory gives a very slow initial speed and hardly any dwell. The pull rod engine would be even slower in initial velocity and piston speed would be more constant an provide less dwell at BDC.

Below 1.5:1 the initial velocity suffers also shown in the plotting of the ratio of 1.2:1 which is too low.

There are many engines that have a conrod ratio above 1.7:1 that perform. Looking at the piston speed graph it would be advantageous to lay around 1.6-1.7:1 if the engine's redline was about 7,000rpm to 8,000rpm

Changing a conrod ratio also changes the torque application angles of the conrod. Maybe the engines you are referring to are trying to achieve a better drivability by changing the position of maximum mechanical advantagein regards to the point of maximum cylinder pressure on the combustion stroke.

I have been talking about breathing not about the combustion cycle.

What you maybe missing from my point is that our engine can utilise the best piston acceleration for breathing while providing the position of maximum mechanical efficiency across the range. This means no matter what ratio is selected for breathing is optimised and independant of the point of mechanical efficiency on the power stroke.

On some other performance engines the valve timing is wilder or in the Honda's case variable valve timing is utilised. Inefficiencies in breathing caused by selecting a non-optimum conrod ratio can be rectified by using these two mods but if we are talking about conrod ratios as it effects piston acceleration and breathing on two identical set up engines the graph shows the sweetspot.

I was talking about the pull rod engine and the effects caused by such designs in regard to optimum conrod ratios.

The chart doesn't lie. It's pure math of a mechanical design of a conrod engine.

Offsetting the gudgeon pin in either direction from standard type settings also change these graphs. Offset used was a standard Evo.

Last edited by revetec; 10-08-2006 at 10:08 PM.

Something is wrong with "100 mm Rod Length" curve.Originally Posted by revetec

"In theory, theory and practice are the same. In practice, they are not."

Dear Manolis,

Again Sorry about the agressive post as I was a bit revved up by the threads because everyone was assuming so much without actually knowing the setup used in our last engine, and I jumped in with both feet.

Let's look at the combustion cycle at 18,000rpm. Such a wide range of rpms would require a longer conrod ratio to work effectivelyas you require to lengthen the band of degrees that the piston is able to transfer power effectively. F1 is hardly the market to compare any on-road engine to.

I would love to see a pull rod engine run and the figures. I see too many new engines that don't make it to production mainly due to unforseen problems and characteristics. I just like to put it out there and healthy controversial discussion is great because it gets everone thinking. I hope the pull rod engine guys read this thread as it may be of some use to them as it maybe something either they have not thought about due to being early in development or they have some theory other than commonly known in the engine design field. In the latter it would be great to hear their thoughts on this subject. I'd love to hear from them as I might be able to help. I would imagine that the pull rod engine will provide optimum performance at very high RPM ranges going on the probable resulting conrod ratio, but maybe not desirable for automotive use as the piston speed will be very slow initially.

I still suggest supercharging of this engine at lower RPM ranges due to the low initial piston speeds. I probably wasn't that clear before. I'm always only looking at operating ranges that engines use in mainstream manufacturing.

Our engine can be easily modified to run any conrod ratio and we have tried a few ratios in our development program using identical setups in the same RPM ranges. We have experienced exactly what the graphs suggest would happen, so it is not just theory, we've done it in practise.

If you are involved in the pull rod engine, get them to contact me. My contact details are posted at http://www.revetec.com

PS. Never doubted the benifits of variable valve timing and theirs is probably good.

Last edited by revetec; 10-08-2006 at 10:26 PM.

Interesting thread. I notice some threads such as those by "richy33" have mysteriously disappeared.

Brad,

You make many claims, but have no evidence for any of them. So understand that people will be sceptical.

I am a chartered professional engineer, not some armchair critic.

The problem I have is with the comments like this;

That statement is absolutely ridiculous. I am an engineer, so I work in the base metric units. m, rad/s, N*m, W. I don't use any silly formulae that have factors to account for imperial units.I'll also state now that the formulas that work out power and torque do not work on our engine so all of you engineers that are trying to work out figures for our engine, your standard engine calculations will not work.

A force is measured in Newtons.

A torque is a Force x a radius = Newton.meters.

Power is torque x rotational speed = Watts.

There is no arguing this, beause that is by definition what those terms are.

If you believe it doesn't work on your engine, then you are doing something wrong when calculating these. This I can guarantee. The power and torque must be calculated at the same shaft at that particular shafts rpm.

Your published test results so far do not show a flat torque curve, it is no flatter than a conventional engine...We have proven in actual testing our flat torque curve and a flat fuel usage over a varying rev range

Well we haven't seen that from your engine either yet, so let's not get ahead of ourselves.Another thing is that the fuel consumption remains constant under full load right through the rev range which is not seen in any other engine in the world.

The "directors announcement" dated 6-Oct-06 states;

What do you mean by "same amount of fuel". Is this a fuel flow rate like L/min? Is so this is impossible, unless the torque at 4,000rpm was half what it was at 2,000rpm.Also noted a further important characteristic aspect namely that our engine at full throttle used the approximately the same amount of fuel at 4,000 rpm as it did at 2,000rpm which was very exciting.

Has a reliable source actually created a full engine characteristics map for this engine? Did they plot pressure-volume diagrams, brake mean effective pressure, thermal efficiency, specific fuel consumption, etc? I am guessing not as the engine threw a cam-belt during the tests at only 4500rpm.

It's probably useless trying to discuss this any further for now, because I have made completely logical observations based on the facts and information available so far.

You have made unproven claims.

If you want to clear some things up, then let's do so.

In order to achieve this, your output shaft must be essentially geared up at a 3:1 ratio, so the output shaft spins 3 times faster than the tri-lobe. Is this correct?I'll tell everyone now that the cylinder heads are operating at the same speed as a conventional engine. ie. The pistons stroke 2 times (1Xup and 1Xdown) per output shaft revolution (the same as a conventional engine),

Don't get me wrong here, I am all for new technologies, especially when it is Australian. But some of the claims so far are pretty wild, particularly when there is no proof what so-ever of any of the claims.

Dear santostripoli,

Thank you for your response. It is hard to discuss in depth what is mostly confidential. You are right by mentioning about Mahindra. I'll state now that no automotive company will talk to anyone with technology without analysing the technology prior and also checking out the company concerned as well as patent protection. No large manufacturer wants to get involved with bogus technology and goes to great lengths to separate themselves from it. Mahindra authorised us to disclose their name and interest in Revetec's technology to ASIC and also to the public. This fact holds weight.

There are currently 3 users browsing this thread. (0 members and 3 guests)